Exploring the Intersection of Cybersecurity and Supply Chain Management in Manufacturing

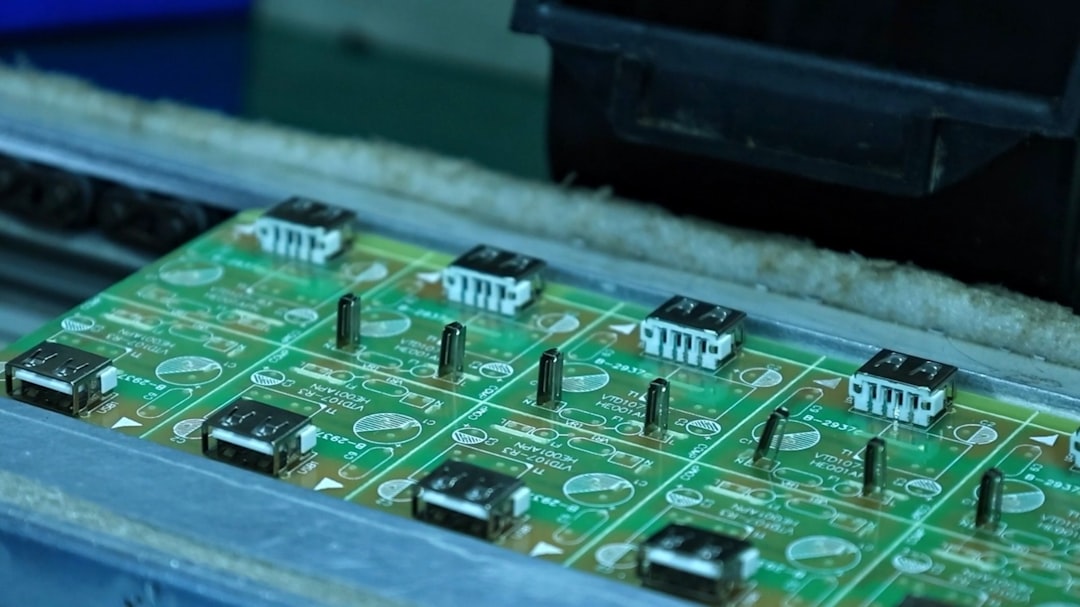

Introduction to Cybersecurity and Supply Chain Management in Manufacturing

In recent years, manufacturing has become heavily reliant on interconnected systems, making it essential to prioritize both cybersecurity and supply chain management. This integration ensures operational efficiency while safeguarding sensitive data. With increasing cyber threats, manufacturers are recognizing the importance of securing their supply chain. Protecting digital assets not only prevents data breaches but also supports uninterrupted production processes. Employing robust cybersecurity measures strengthens the entire supply chain, minimizing vulnerabilities and enhancing trust among stakeholders. As a result, understanding how these elements intersect is crucial for the success and resilience of manufacturing businesses.

Importance of Cybersecurity in Manufacturing

Image courtesy: Unsplash

Image courtesy: Unsplash

In the world of manufacturing, cybersecurity plays a crucial role in protecting complex systems and operations. As manufacturing systems become more connected and reliant on digital technologies, they become vulnerable to cyber threats. Organizations need to understand the importance of cybersecurity to safeguard their operations and maintain trust with their partners and customers.

Threats to Manufacturing Systems

Manufacturing systems face various cybersecurity threats that can disrupt production processes and compromise sensitive data. Common threats include malware attacks, ransomware, and phishing. These types of cyber attacks exploit vulnerabilities in software and hardware, potentially halting production lines or damaging industrial equipment. Additionally, industrial espionage can target proprietary data, leading to significant financial losses and a competitive disadvantage in the market.

Impact on Supply Chains

An attack on a manufacturer’s cybersecurity does not only affect the company but can have far-reaching implications throughout the supply chain. A single breach can interrupt the flow of goods, delay delivery schedules, and create bottlenecks—impacting suppliers, partners, and customers. The supply chain is a highly interconnected network, and vulnerabilities in one link can spread quickly to others. Cyber attacks can also lead to financial losses due to disrupted production and the cost of restoring systems to normal operations. Furthermore, damaged reputations can result in a loss of trust among stakeholders, leading to long-term business ramifications.

Data Protection and Compliance

Protecting sensitive data and ensuring compliance with regulations is another critical concern for manufacturers. Many manufacturers handle proprietary information and customer data that must be kept secure. Additionally, they must comply with industry standards and regulations, such as the General Data Protection Regulation (GDPR) and the National Institute of Standards and Technology (NIST) guidelines. Non-compliance can result in severe penalties and legal issues. Therefore, manufacturing companies must implement robust data protection strategies to prevent unauthorized access and data breaches.

Securing the Manufacturing Supply Chain

Image courtesy: Unsplash

Image courtesy: Unsplash

Ensuring the security of the manufacturing supply chain requires a comprehensive approach that includes assessing risks, implementing cybersecurity measures, and fostering collaboration with suppliers and partners.

Risk Assessment Practices

Risk assessment is the first step in securing the manufacturing supply chain. This involves identifying potential vulnerabilities in systems and processes, evaluating the likelihood of threats, and determining their potential impact. Manufacturers should conduct regular risk assessments to stay ahead of evolving threats. By understanding their risk profile, companies can prioritize their security efforts and allocate resources effectively. A robust risk assessment framework can help organizations identify critical areas needing improvement, ensuring vulnerabilities are addressed proactively.

Implementing Cybersecurity Measures

Once risks are assessed, manufacturers need to implement strong cybersecurity measures. These can include:

– Installing firewalls and anti-virus software to detect and block malicious activities.

– Employing intrusion detection systems to monitor network traffic for suspicious behavior.

– Encrypting sensitive data both in transit and at rest to prevent unauthorized access.

– Implementing access controls to restrict users’ ability to enter sensitive areas of the system.

– Training employees on cybersecurity best practices to reduce the risk of human error.

It’s important for manufacturers to maintain an up-to-date cybersecurity infrastructure and continually review their systems to protect against new threats. Cybersecurity is not a one-time effort; it requires ongoing management and adaptation to stay effective.

Supplier and Partner Collaboration

Collaboration with suppliers and partners is essential for a secure supply chain. Manufacturers should establish clear cybersecurity expectations with all parties involved. This includes conducting third-party cybersecurity assessments to ensure partners adhere to security standards. Communication should be open and continuous to address potential risks and emerging threats.

Moreover, manufacturers can benefit from creating a community of trust where information about threats and best practices is shared. This collaborative approach ensures all parties are aware of potential risks and work together to mitigate them. Cooperation strengthens the entire supply chain network by ensuring that suppliers and partners are equally vigilant in maintaining robust cybersecurity measures.

In conclusion, the intersection of cybersecurity and supply chain management in manufacturing is critical for protecting operations and data from potential threats. By understanding the importance of cybersecurity, assessing risks, implementing strong measures, and fostering collaboration, manufacturers can secure their supply chains and ensure smooth and efficient production processes.

Conclusion

In conclusion, the intersection of cybersecurity and supply chain management in manufacturing is a crucial area that requires focused attention. As manufacturers continue to embrace digital transformations, the vulnerabilities within supply chains become more pronounced. It is imperative for organizations to implement robust cybersecurity measures to ensure the security and integrity of their supply chain operations. By integrating advanced security protocols and continuous monitoring, manufacturers can better protect themselves against potential cyber threats and disruptions, securing a resilient future for their operations.